The benefits of regulated ventilation

Natural and industrial ventilation systems

Natural ventilation systems ensure better air quality. Improved ambient air is essential for the health, well-being and concentration of all employees. Our air consists mainly of the gases nitrogen and oxygen. If other substances are measured in the air, such as particulate matter, nitrogen dioxide and ozone, this indicates air pollution, which negatively impacts human health and the environment. Air quality is therefore determined by the level of pollutants in the air and is hence a measure of the purity of our air. Reasons for poor air quality include air pollution, heat load, an increased CO2 concentration or excessive humidity. Air pollutants can arise from various sources. A distinction is made between natural and Human caused sources.

Natural sources of particles and gases (in particular nitrogen dioxide NO2) include:

- Soil particles, mineral dust

- Sea salts

- Pollen Volcanoes

- Forest fires

- Microbiological processes in soils and during volcanic eruptions

Human caused sources include:

- Combustion processes

- Heating systems

- Industrial plants

- Motor vehicle traffic

It is essential to have a high level of air quality in industry and commerce. Poor air quality can have serious consequences for people and machines. This can result in accidents at work, illness, errors, a reduction in human performance and expensive repairs due to contamination and thermal load on machines. Careful and, above all, regular ventilation of workplaces via the windows is therefore essential. Measures such as shock ventilation, cross ventilation or window ventilation are not sufficient for the industrial sector. Regular ventilation can ensure good air quality and save high costs. Natural ventilation systems also ensure the efficiency of the company.

Occupational exposure limit through natural ventilation

Mechanical processes or turbulences, thermal and/or chemical processes as well as condensation or dispersion can produce airborne particles such as dust, smoke and mist. Suspended particles, gases and vapours are substances that are harmful to people when present in high concentrations in the air. The occupational exposure limit value (OEL) specifies the limit value for the time-weighted average concentration of a substance in the air at the workplace in relation to a given reference period.

In other words, how high the concentration of a substance in the air may be, that no health damage to persons is to be expected. The OELs can be used to check whether the exposure of employees to hazardous substances in the air at the workplace is safe and permissible. However, it does not generally exempt exposed persons from medical monitoring of their state of health. If the exposure is too high, measures such as extraction systems must be installed. The occupational exposure limit value is calculated as follows:

The concentration (C) of a substance in the air is the quantity of this substance in the unit of air volume. It is given as mass per unit volume or, in the case of gases and vapours, also as volume per unit volume. The mass value is to be used as a reference value for the working range analysis. The corresponding units are mg/ m³and ml/ m³ (ppm). The conversion is carried out according to

C (ml⁄(m³))=(molar volume in l)/(molar mass in g) C (mg⁄(m³))

The recommended molar volume is 24.1 litres, based on a temperature of 20°C and a pressure of 101.3 kPa. The concentration for suspended particles is given in mg/m³ for the operating conditions prevailing at the workplace.

The occupational exposure limit values apply to liquid mixtures of substances and to components of liquid mixtures of substances consisting exclusively of hydrocarbons, whereby hydrocarbons are understood to be organic compounds consisting only of carbon and hydrogen.

The occupational exposure limits are to be applied, as such or as components in mixtures, to hydrocarbon mixtures with C-numbers up to C14, which have a boiling range up to approx. 250°C, a benzene content < 0.1% by weight and do not contain any non-hydrocarbon additives.

Regulations for workplaces

The regulations on health and safety at work set out general protection objectives to ensure the health and safety of employees at their workplace. These objectives serve as guidelines for employers to take appropriate measures to protect their employees. These measures are based on current state of art, occupational medicine and hygiene, as well as other proven ergonomic findings for setting up and operating workplaces. They are intended to assist employers in preparing risk assessments and in identifying measures for the safety and health protection of employees. The following values are recommended:

Please be aware that each country has its own guidelines on air quality and occupational health and safety. These must be observed and complied with.

AIR QUALITY - TEMPERATURE

The temperature in workrooms should not exceed 26°C. Higher temperatures are only permitted if the outside temperature is above 26°C. Additional measures such as reducing internal thermal loads, night ventilation, early morning ventilation or relaxing clothing rules can help to reduce the indoor air temperature. At temperatures above 30°C, further measures must be taken as described above. At temperatures above 35°C, further measures must be taken, such as air showers, cooling phases or heat-protective clothing.

These technical rules are recommended for workplaces and define the rules for room temperature. They are divided into the following sections:

- objective

- area of application

- definitions (e.g. how is room temperature defined?)

- room temperatures

- deviating/supplementary requirements for construction sites

air quality - humidity

External weather conditions in combination with technical processes and moisture input from people, for example breathing, can result in high humidity in the room. A high level of humidity can promote the humidification of building components or mould growth. To counteract this process, it is recommended that a maximum relative humidity of 80% at an air temperature of 20°C is not exceeded. This is staggered in individual steps up to an air temperature of 26°C with a maximum relative humidity of 55%. If this cannot be complied with, the employer is advised to take countermeasures. Measures would include dehumidifiers, for example, which are nowadays usually part of complex air conditioning systems.

There is also a recommendation for air temperature as a function of humidity. If there are operational or work-related humidity loads in the work area, the following values should not be exceeded for physiological reasons:

If the nature of the operation requires higher humidity levels, for example food production, greenhouses or swimming pools, this does not apply.

air quality - CO2 concentration

The CO2 concentration in the air is given in parts per million (ppm) or as percentage and is a measure for assessing air quality, particularly in the case of substance loads caused by people. According to VDI 6022-3, the concentration of CO2 is divided into three or four quality classes.

The measures are advised on the basis of the quality classes. The workplace limit value for CO2 (RAL1) should be 1000ppm or 0.1%, which is referred to as "good air".

For comparison, the average CO2 concentration in the countryside is 300ppm and in the city 700ppm. If values of up to 2000ppm are reached, ventilation behaviour should be improved. This is achieved by natural ventilation. Other measures are also recommended.

Air quality in industrial companies

High air quality is essential in industry and commerce and is still not given enough consideration in many industrial companies. Whether in new or existing buildings, good ventilation protects people and machines and can also be installed afterwards. The advantages are obvious:

- By installing suitable ventilation concepts in your company, you increase the productivity of your employees and at the same time reduce the likelihood of errors.

- In the long term, you will increase the motivation of your employees and reduce sickness-related absences, which occur more frequently when the air is poor

Extensive research shows that better indoor air quality (low concentrations of CO2 and pollutants and high ventilation rates) can lead to productivity improvements of 8-11%, while, at the same time, poor air quality leads to increased absenteeism due to illness.

air exchange rates

To ensure healthy levels of indoor air, attention should be paid to the air exchange rate at the workplace, which refers to the air exchange rate per hour. A higher air exchange rate is used at production sites where there is a particularly high level of heat, CO2, humidity or soiling due to operations.

Natural ventilation

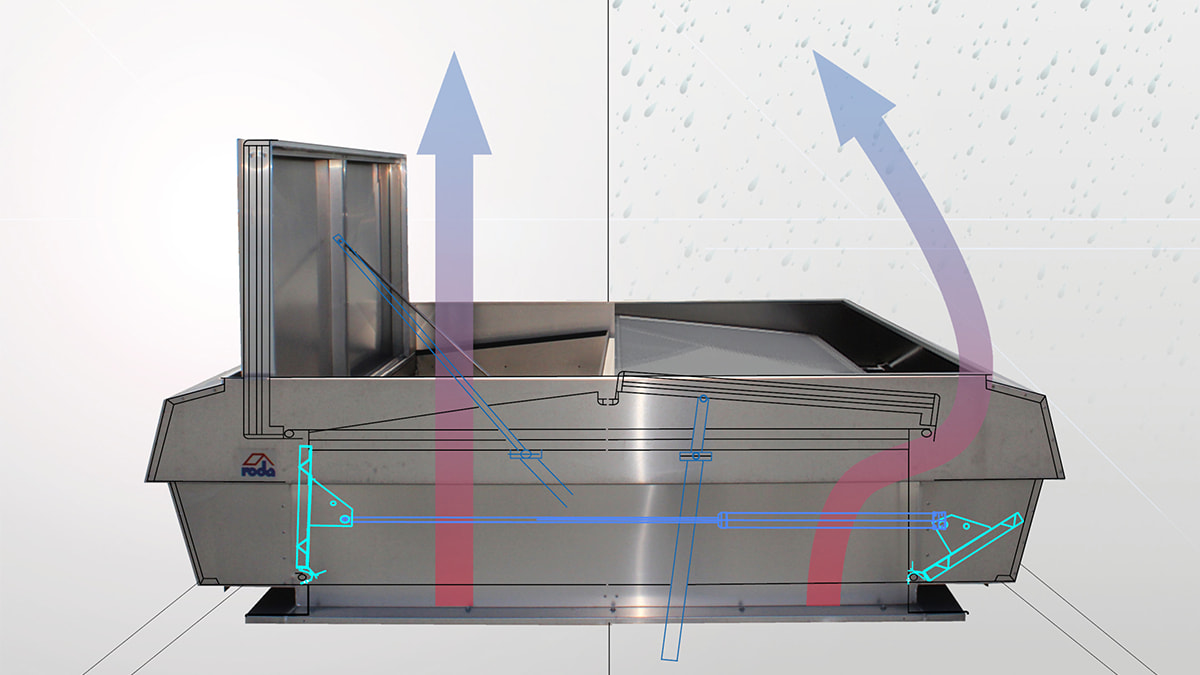

With natural ventilation, air renewal or air exchange is generated by utilising the natural pressure differences due to wind and/or temperature differences between outside and inside. No power-driven fans are required. Natural ventilation units in the form of built-in double flap ventilators, single flap ventilators and louvre ventilators work according to the laws of thermodynamics. By supplying fresh outside air via air inlets from lower parts of the building and discharging the exhaust air via roof openings, the thermal buoyancy ("stack effect") caused by temperature differences is utilised to ensure continuous air renewal.

Advantages of natural ventilation:

- Low purchase costs

- Very low operating costs

- Very quiet

- No noticeable airflow

- Hardly any maintenance required

- No additional space required

Natural ventilation systems and energy efficiency

Up to 40% of the energy consumed by electrical machines is released into the room air as heat. By installing natural ventilation units, the resulting heat load can be dissipated cost-effectively without having to resort to expensive and environmentally harmful cooling systems. Even at the height of summer, when temperatures reach above 30°C, the building temperature can be lowered overnight in an energy-efficient manner with the help of night cooling.

An intelligent combination of heating systems and controlled natural ventilation can ensure a pleasant indoor climate all year round. A study has shown that up to 60% of energy can be saved through building system technology in the automation of ventilation alone. This saves money and improves the energy efficiency of your building. Fans and ventilation shafts can be dispensed with. This significantly reduces construction costs. Utilising freely available natural resources also protects the environment. Carbon dioxide emissions are reduced. This has far-reaching consequences because around 50% of all energy worldwide is used for air conditioning in buildings.

Mechanical ventilation

Mechanical ventilation transports air via flow motors. Supply air and exhaust air are transported directly to the workplace via duct systems. Compared to natural ventilation, the acquisition and operating costs are significantly higher, and the maintenance requirements of the more complex and larger systems are also significantly higher due to hygiene.

Advantages of mechanical ventilation:

- Flexibly expandable

- Pollutants can be filtered

- Ventilation available everywhere (if sufficient space is available)

Individual positioning of the supply air openings in the room (good mixing of fresh air can be achieved throughout the room, localised supply air openings at workstations)

Ventilation concept according to DIN EN DN EN 16798-3

DIN EN 16798-3 "Ventilation for non-residential buildings - Requirements for the performance of ventilation and air conditioning systems and room cooling systems" defines guidelines for the design of ventilation and air conditioning systems in non-residential buildings intended for human occupancy to create a comfortable and healthy indoor climate in all seasons with acceptable installation and operating costs and is the successor to the former DIN EN 13779 "Ventilation for non-residential buildings - General principles and requirements for ventilation and air conditioning systems and room cooling systems". The indoor air quality is categorised as shown.

In existing buildings: Additional installation of natural ventilation

Often, only a fraction of the daylight elements in an existing building are used for ventilation. The result is poor air quality and high follow-up costs due to poorer productivity and greater susceptibility to errors. With suitable ventilation concepts and natural ventilation systems in your company, you can increase the productivity of your employees and reduce the likelihood of errors at the same time. In the long term, you will increase your employees' motivation and reduce sickness-related absences, which occur more frequently when the air quality is poor. High air quality is therefore essential in commerce and industry.

In addition to the complete refurbishment of your existing skylights, roda also offers the renewal/replacement of individual elements that can be installed directly into your structures. For you, this means that you can expect maximum flexibility in the refurbishment, with a customised solution specifically for your building project.

This specifically means:

- Renovation during ongoing operations

- Individually and precisely manufactured windows to the millimeter

- Existing construction can be utilized, thereby eliminating the need for additional roofing work

- Adaptation to the needs of your business (e.g., insect screens)

- Maintenance can also be performed by roda

Our customers put their trust in us and our solutions

Renovation example Steinel

"With our injection moulding machines, waste heat is the greatest challenge for us in creating good working conditions. I would not have thought it would be possible to overcome this with natural ventilation. But with the appropriate systems, we have seen a significant improvement in working conditions. We would like to thank roda for their excellent advice and look forward to further projects."

Sample calculation:

- Building height: 6 m

- Plastic injection moulding machines of 1.5 K heating per m of hall height

- V= root (g x h x delta T/TA) TA (average temperature in Leipzig) set at 10 degrees (283K)

This results in:

- V= (9,81m/s x 6 m x 9K/283K)

- V = 1,36 m/s

Fair weather ventilation 16 x 3,75 m² = 60 m² x 1,36 m/s = 293.760 m³/h

Bad weather ventilation 16 x 1,5 m² = 24 m² x 1,36 m/s = 117.504 m³/h

Project inquiry

Are you looking for support for your next project? We are happy to offer our experience!